Springback

“Achieve enormous time savings in die tryout with global surface morphing”

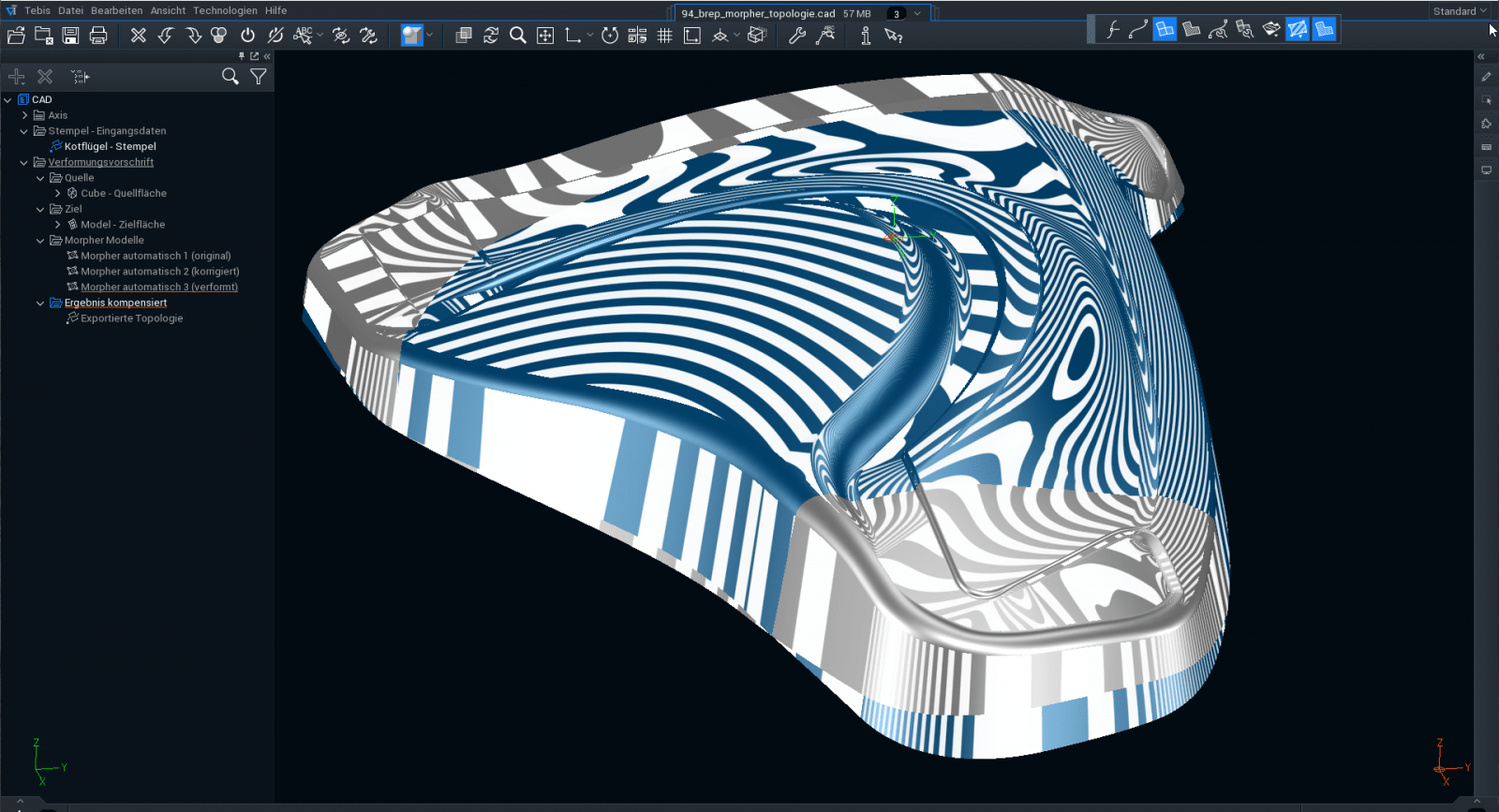

The elastic properties of the sheet-metal cause springback after the forming of sheet metal parts. This springback is compensated in the sheet-metal die, so that the part is initially formed to an “incorrect” geometry and then springs back to yield the desired geometry. Manually grinding springback in the die is extremely time-consuming in the tryout presses Process reliability is also affected.

Tebis therefore uses global morphing rules with which individual surfaces can be deformed completely automatically based on FEM analyses, measurements, digitized data or experience – and feedback is compensated, greatly reducing the number of correction loops. The qualitative surface properties such as segmentation, polynomial degree, and transitions are optimally adjusted to the morphing rule in this CAD-based morphing. Analysis functions indicate adherence to the morphing rule and to the quality of the formed surfaces.

Contact Form

Address

Bursa

Alaaddinbey Mah. Ciftlik(380) Cad. No:7

16285 Nilüfer Bursa / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (224) 211 62 00

İstanbul

Sanayi Mahallesi Teknopark Bulvarı No:1/3A

Z04, 34906, Pendik, İstanbul / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (216) 521 53 85