Mill

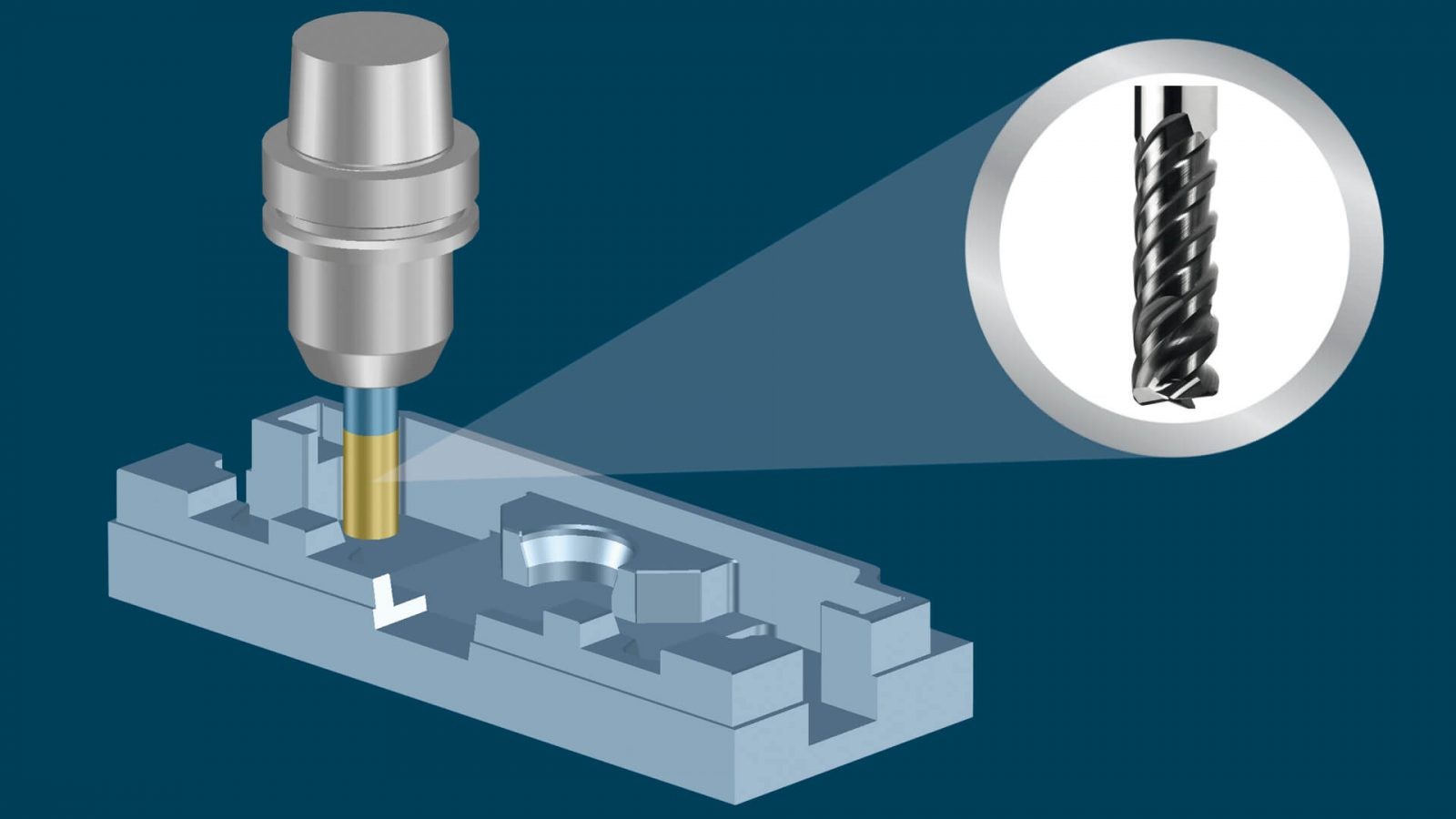

2.5 MILLING

“Simple and easy to automate”

Tebis contains all the strategies you need to quickly machine open and closed 2.5D geometries, including multi-sided machining. Options for roughing and finishing walls and bottoms are integrated. This also simplifies NC programming: This lets you manufacture special geometries with just a single function.

The key advantage: NC programming of prismatic ruled and free-form geometries can be easily automated using Tebis feature technology for 2.5D milling – and of course automatic feature detection is also included.

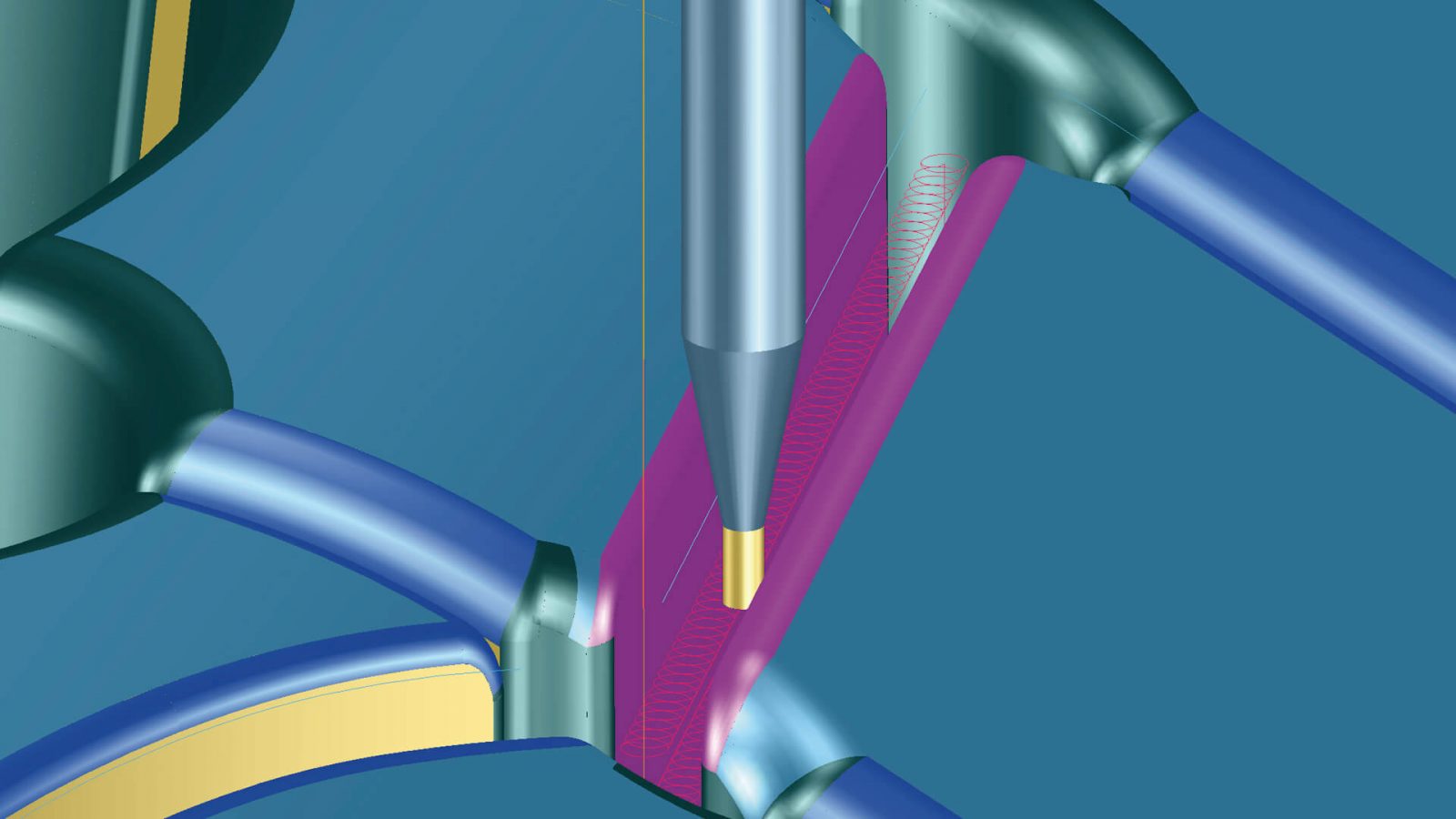

3D MILLING

“The reliable and efficient path to premium surfaces”

The 3D milling strategies can be used to create 3-axis and 3+2-axis NC programs for roughing, finishing and residual stock machining. You can avoid collisions during calculation. For example, the tool automatically avoids collisions or reduces areas at risk, depending on the application. In combination with the precise simulation technologies and harmonic slope-adjusted NC paths, optimal traverse paths are generated for the machine axes in 3D milling.

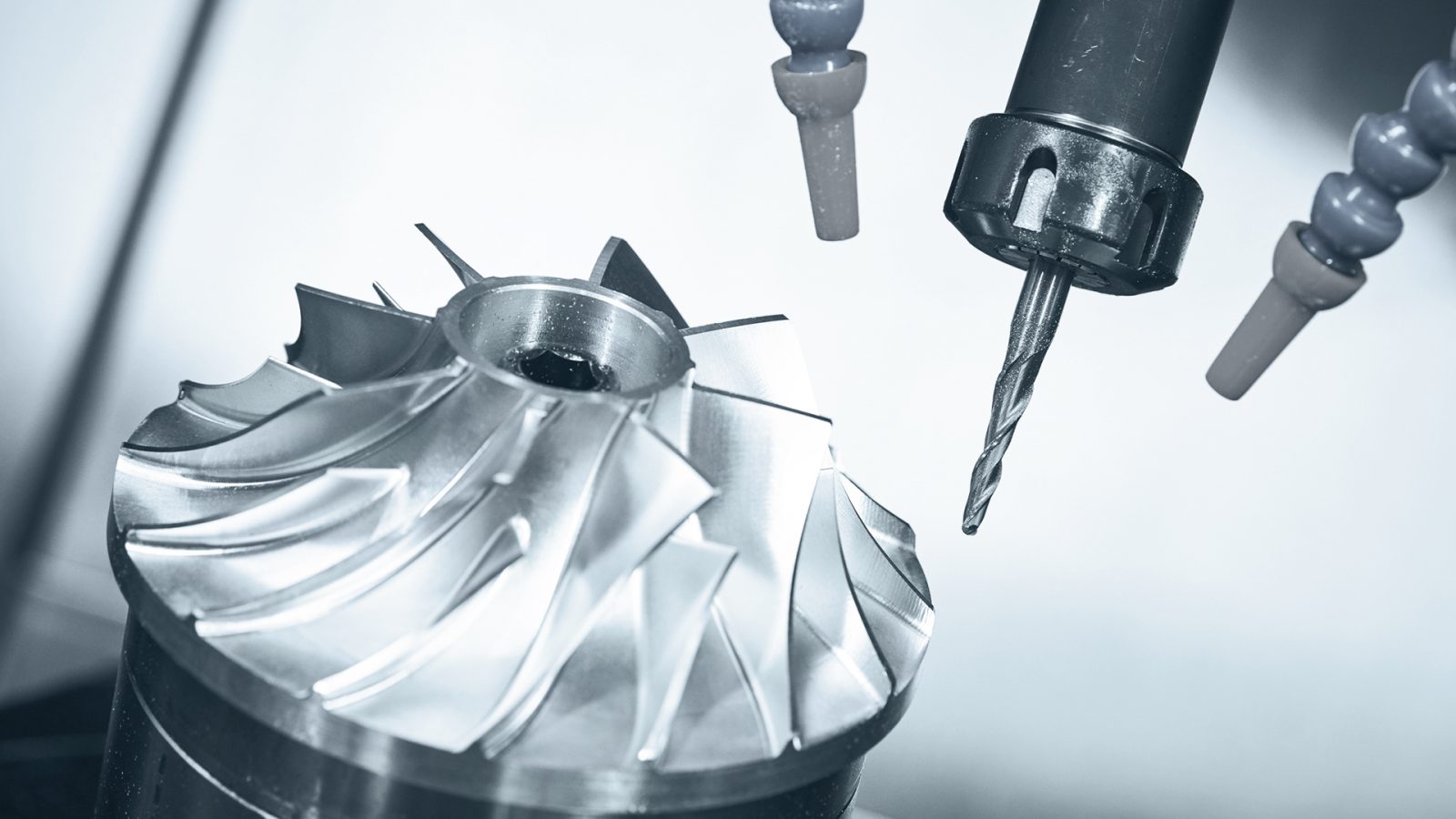

5D MILLING

“Easily, quickly and reliably manufacture 3D surfaces”

5-axis simultaneous milling quickly and efficiently produces high-quality surfaces unlike any other milling method. Tebis lets you use the full potential of your expensive high-performance machines: Collision-free programs can be easily planned and calculated for all multi-axis machining operations. Homogeneous toolpaths with low tool wear and checked for tilt direction are automatically generated.

RIB and SLOT MILLING

“Automate manufacturing of slots”

Enjeksiyon kalıplarının ejektör tarafındaki gibi derin yuvalar, bileşen sağlamlığına katkıda bulunur. Bu yuvalar, frezeleme veya dalma erezyonu ile üretilebilir. Tebis, bileşendeki bu girintiler için hangi üretim yönteminin en uygun olduğuna karar vermenize yardımcı olacak pratik analiz fonksiyonları sunar. CAM programları, analiz sonuçlarına göre otomatik olarak oluşturulur.

TRIMMING

“Greater productivity through offline programming”

Tebis helps you master the challenges in 5-axis trimming: You can quickly and reliably create toolpaths for trimming your parts – perpendicular to the part surface or parallel to a flank – even for complex geometries. Collisions with other part areas, clamping devices or machine components are not possible. Offline programming lets you avoid tedious teach-in and unproductive use of the machine. This applies to both vacuum-formed parts made out of thermoplastic materials and to parts made out of composite materials (e.g. carbon) as well as to parts clad with wood and with other natural materials.

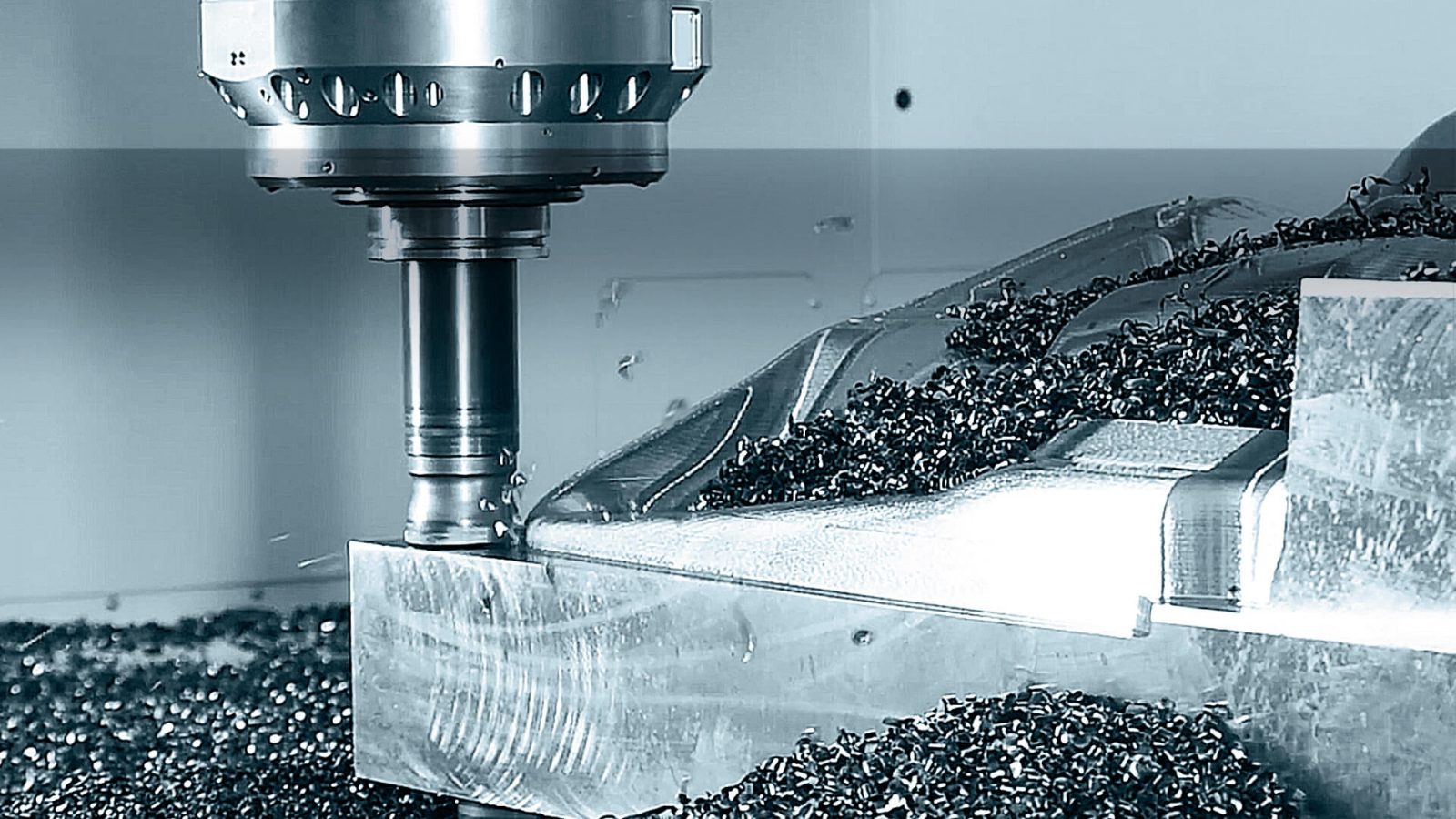

HIGH PERFORMANCE CUTTING

“High-performance cutting (HPC) for maximum material removal rate”

The goal of every roughing operation is to remove as much material as possible within the shortest possible time. This is an enormous stress test for the cutter, which often ends up in full contact. Tebis therefore uses options for full-cut handling as well as for full-cut avoidance. In full-cut handling, feed rates are automatically reduced, or full-cut areas are machined trochoidally. In full-cut avoidance, the path layout is automatically adapted to the geometry without full cuts.

Full-cut avoidance is used in adaptive roughing. This is where it really counts: Compared with conventional roughing, special HPC cutters achieve extremely high material removal rates at constant cutting conditions with higher cutting speeds and feed rates, smaller lateral stepovers and very large cutting depths – and time savings of over 60 percent are easily possible. Adaptive roughing strategies for HPC milling are especially suitable for parts with many deep cavities. Hard materials can also be machined very easily in this way.

HIGH FEED CUTTING

“Suitable for roughing and prefinishing”

High feed cutters or HFC tools (high feed cutting) enable high cutting performance with high feed rates and cutting speeds on modern milling machines. These high feed cutters and high-performance cutters have a special cutter geometry with multiple cutting edges. They’re available with and without indexable inserts.

These tools can be implemented extremely efficiently in combination with Tebis for both roughing and prefinishing: NC programming in Tebis is always performed using the real cutter geometry, and the maximum possible residual stock is removed – the optimal preparation for final finishing.

CIRCLE SEGMENT CUTTERS

“Smooth surfaces with large path distances”

For circle-segment cutters – also known as barrel cutters – the radii in the cutting areas are significantly larger than for conventional ball cutters. They are modern high-performance tools for high-efficiency prefinishing and finishing of planes and free-form surfaces. The same surface roughness is achieved on the part with a significantly larger path distance, which greatly reduces your machining times while achieving outstanding surface quality

Contact Form

Address

Bursa

Alaaddinbey Mah. Ciftlik(380) Cad. No:7

16285 Nilüfer Bursa / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (224) 211 62 00

İstanbul

Sanayi Mahallesi Teknopark Bulvarı No:1/3A

Z04, 34906, Pendik, İstanbul / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (216) 521 53 85