SERVICES

"We do A Class surface work"

Surface Development

Surface development is a service we provide to companies as Redoks Engineering in order to increase the surface quality and reduce the try-out times and hand leveling after processing. We offer solutions to your time and money consuming problems such as surface offsetting and radius reduction. We save both time and money.

While making surface repairs with Tebis’ advanced surface creation options, on the other hand, outer sheet, inner panel, lens surface, etc., which is called the visual part. We also do A Class surface work for visual parts. In all of these works, we save your company time from post-production rework, hand leveling and try out times.

"Tebis provides you time and money with its springback service"

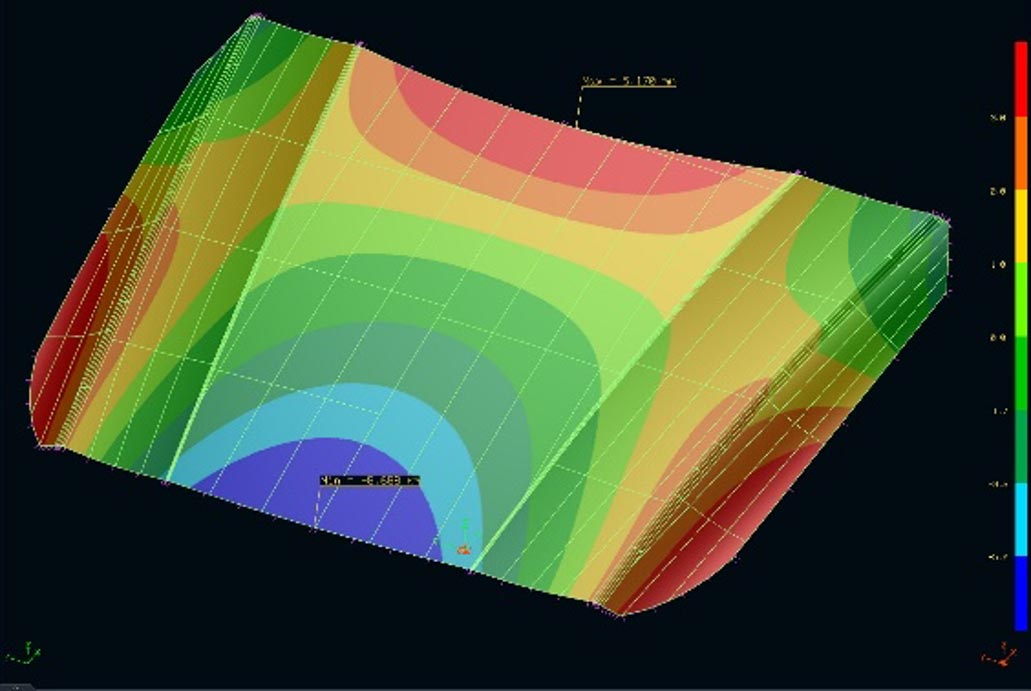

Spring Back

Sheet materials pressed under the press stretch back to a certain extent due to their elasticity and the part takes a different form than desired. Tebis provides the desired amount of springback value to the designed surface in this process, allowing you to create the part you actually want to achieve.

Your mold surface, which is processed with the surface to which the amount of stretching has been added, helps to regain these times lost during the try-out periods and when hand leveling is required. Thus, your try-out times become much more profitable with the advanced functions of Tebis. The days and weeks you lose under the try-out are reduced to hours. As Redoks Engineering, we provide you with time and quality with this service.

"We offer reverse engineering solutions to your projects"

Reverse Engineering

As Redoks Engineering, we offer solutions for obtaining 3D CAD data of digitized physical parts with 3D scanning technologies. In particular, we create surfaces on these data by using STL data in the form of a triangular mesh obtained by methods such as optical scanning. The surfaces created with as few patches as possible on the model are of a quality that can be used without any problems in operations such as CAD operations and FEM mesh creation.

"Redoks Engineering Virtual machine service"

Virtual Machine

As Redoks Engineering, we provide Tebis Virtual Machine service. With this service, which we have created by our own teams, we ensure that you work safely, especially on your workbenches with 5 or more axes.

The virtual machine is the digital twin of your real machines. It is created on the designed CAD model of your machines and you have the chance to see and prevent the collisions that may occur during processing in the virtual environment. In Tebis, you control the collision with your virtual machine, while also controlling the G00 movements. While reducing time losses, CNC machine control is completely in your hands at the same time. In this way, you can safely operate your machines with NC codes.

"We create a properly configured Post Processor for your machines"

Post Processor

The Post Processor converts the toolpaths created in Tebis into NC codes that the control unit of your CNC machine can understand. NC codes compatible with machine control units enable your CNC machines to work efficiently with all their functions.

As Redoks Engineering, we create a properly configured and developed Post Processor for your benches thanks to this service we provide with our own team. We convert toolpaths into editing-free NC code for use on a variety of CNC machines. Thus, we ensure that your machines are operated smoothly without the need for any additional software or company.

"Save time and labor with automation"

Automation

Automation is the system that Tebis has been working on since its establishment. Tebis aims to provide added value by developing this system, which makes things easier and provides convenience in both time and workforce.

As Redoks Engineering, we integrate your company’s manufacturing habits into Tebis. First of all, we set up a smart manufacturing system by matching your CAM preparation habits in the CAD part, then a plate machining, mold or part surface machining, hole and pocket machining habits with your tool library. We integrate your machine simulation and clamping systems into the automation system.

We reduce the hole and pocket programs that you have to do many times a day and spend a lot of time to a few minutes by simply saying find the feature and process them. We enable you to program more easily and systematically by standardizing the setup and stok values you make when starting the part, the toolpath and cutting values you enter according to materials and tools, and the clamping systems you use in machine simulation. With these processes, we make your working conditions more efficient.

"Redoks Engineering adds value to your company with its consultancy service"

Consultancy

We offer you ways to work efficiently with our knowledge of processing, materials, tools and workbenches, especially in the automotive industry. We examine these processes from CAD to CAM, from your machines to your machining habits and from the clamping systems used to your tools. We create added value by saving you the time and labor lost during production. We add value to your company with our consultancy service.

"We shorten your product development process with Tebis"

Product Development

Redoks Engineering provides service with the Tesbis system at all stages of the product development process.

"Take advantage of 5-Axis production"

5-Axis Machining

Redoks Engineering provides production services for the machining industry with 5-axis machines.

Contact Form

Address

Bursa

Alaaddinbey Mah. Ciftlik(380) Cad. No:7

16285 Nilüfer Bursa / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (224) 211 62 00

İstanbul

Sanayi Mahallesi Teknopark Bulvarı No:1/3A

Z04, 34906, Pendik, İstanbul / Turkey

Work Times: Monday – Friday: 09:00 – 18:00

T: +90 (216) 521 53 85